Product Detail:

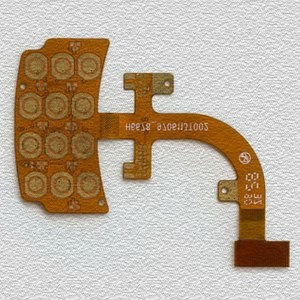

Flexible PCB-flexible printed circuit, referred to as FPC. It is a conductor circuit pattern made by light pattern exposure transfer and etching process on the surface of the flexible substrate. The surface and inner layers of double-sided and multi-layer circuit boards are electrically connected through metallized holes. The surface of the circuit pattern is protected and insulated by PI and glue layer.

Flexible PCB is mainly divided into single-sided flex PCB, hollow FPCB board, double-sided Flex PCB, ,4 layer flexible pcb and other multi-layer flexible board, rigid-flexible PCB board.

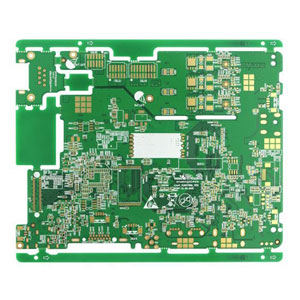

Rayming provide 1- 8 Layer Flexible PCB Manufacturing services for both quick turn prototypes and production quantities. also we provide Flexible circuit fabrication and assembly services, Our Engineer provide free DFM Checking.

Specification of Flexible PCB

When designing flexible circuits, some specifications need to be considered. These specifications will help flex pcb manufacturers know what to include.

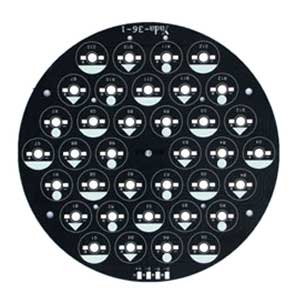

1. Number of layers

There are different types of flexible printed circuit boards. This is why it is necessary to specify the type that suits your needs. Different circuit board types have different number of layers. According to your specifications, the number of layers can be one, two or more layers.

2. Surface treatment

This has different forms. There is no specific surface finish for a specific application. With this, you can freely choose from the surface treatments available in the industry. These include gold and soldering, immersion tin, immersion silver, hot air soldering level, organic coating OSP, electrolytic tin plating, etc.

3. Solder mask

This is also called solder mask coating or solder resist. They have different forms. It is important to specify the type of solder mask required and where you want or need it.

You can either place it on both sides of your flex PCB or on one side. Your flex PCB FPC type will also guide you on where the solder mask should be placed.

4. Copper weight

This is also very important. The weight of copper will be determined according to your application. Please note that the weight of copper may affect flexibility. Therefore, please make sure that you do not compromise on the flexibility of your design.

5.Spacing

Spacing has a great influence on the function of the design. If the spacing is small, the function may be affected, which may cause a short circuit in the entire circuit. Make your device specifications as wide as possible. The wider it is, the higher the capabilities of your device.

6. Hole size

The hole should be tighter to prevent any problems with the drilling. This ensures that the components mounted on the substrate are tighter when the circuit is bent.

7. Quality test

Your design must go through this process. Quality testing reveals how your design will work.

8. Quality compliance

This ensures that the design meets the quality standards set by different agencies. The main quality standards that the design must meet include ISO 9001:2000 and RoHS.

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited