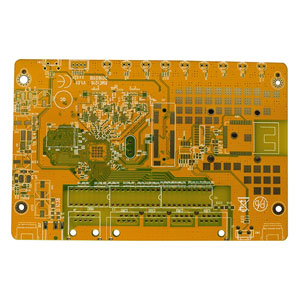

Product Detail:

Hecheng Fast Electronic Technology can providing high quality bare printed circuit boards and printed circuit board assemblies at very lower cost, outstanding service and timely delivery. A team with more than 2 decade of experience have developed a reputation for consistently delivering quality products and services on time. Our quality processes are to international standards and we have ISO certifications. We are helpful, attentive and supportive with a proactive approach to help you win in competitive markets.

Considerations to pay attention to when manufacturing large PCBAs:

Manufacturing large PCBAs brings some challenges that regular size PCBAs don't have to deal with. The following are some areas that may be affected by the big board:

Rapid manufacturing: Not all manufacturing suppliers are set up for rapid manufacturing processes. PCB technology, such as high-speed design, impedance-controlled copper thickness, and copper volume used for routing, will slow down the rapid manufacturing speed of circuit boards. When the circuit board is larger than the industry standard, these same factors will further slow down the production speed of the circuit board.

High-level manufacturing: PCB manufacturers obtain CM qualifications based on their ability to manufacture circuit board layers. Typical limits are two to four floors, six to ten floors, and twelve floors and above. The higher the number of layers, the more professional the supplier must be, which will also slow down the manufacturing speed of large PCBs.

Price: PCBA is built on the panel. Since you usually pay for the price of the panel, the more PCBs manufactured in the panel, the lower the unit cost per PCBA. Since large boards are not suitable for traditional panel sizes, you will pay more for the unit compared to smaller boards.

Thermal effects: The thickness and number of power and ground layers in larger circuit boards may have a thermal effect on the soldering process. The more metal on the board, the more heat and soldering materials are required. This may cause the solder reflow profile optimization to take longer than normal to define.

A large number of connectors: If there are multiple connectors on the backplane, more effort is required to create and use test fixtures. Generally, the test fixture needs to touch all connector pins to fully test and verify the PCB manufacturing and assembly process. Due to the large number of connector pins on the backplane, this may result in longer test times.

All of these situations can be easily handled by a CM who has experience in handling large circuit boards. When choosing CM to build a large prototype board for you, there are some specific things to consider.

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited