What is assembly electronics?

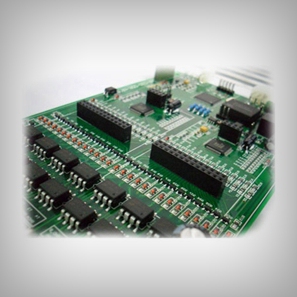

Assembly electronics is a process in which various electronic components, electromechanical components, and structural parts are assembled in specified positions according to design requirements to form a complete electronic product with certain functions. Its core is to assemble the components into circuit board components or assemblies (PCBA) with certain functions. In-circuit board assembly can be divided into two types: automatic assembly and manual assembly. Machine assembly mainly refers to automatic iron sheet assembly (SMT), automatic plug-in assembly (AI), and automatic welding, and manual assembly means manual plug-in, manual repair welding, repair, and inspection, and so on,The assembly content of electronics includes division of unit circuits; layout of components; installation of various components, parts, and structural parts; assembly of the whole machine. The assembly of electronic equipment is divided into different levels according to the size, size, complexity, and characteristics of the assembly unit.

What are the main factors affecting the cost of assembly electronics?

First of all, starting from the material, the steel used by different manufacturers is different. On the surface, it is the same piece of equipment, the price is also very different because the materials used are different in thickness. To sum up, there are several main factors including PCB technical requirements; surface mounted technology or through-hole technology; single-sided or double-sided SMT assembly; total number of components; types and versatility of components; the complexity of printed circuit board assembly; the component shapes used and the manufacturability of the assembly.Second, different equipment has different functions and different prices. The main function of the assembly electronic production line is the production equipment that assembles electronic product components. The more complete the electronic assembly production line, the higher the production efficiency. But all of this requires investment at fixed costs, which will naturally be reflected in the price of manufactured goods.

Third, the well-known assembly electronics companies in the market are those flooded with advertisements. Sometimes, companies that invest a lot of advertising may not necessarily have good equipment. Some of them may also be engaged in e-commerce sales. They do not have their manufacturing plants, but only agents or consignment sales agents who need profits, which is why the market price has doubled several times.

Finally, equipment after-sales services will also affect the cost.

What services do we offer?

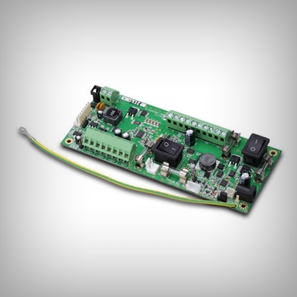

Over the years, our assembly electronics services have played a vital role in the creation of many innovative products ranging from simple gadgets to advanced equipment commonly used by industry and consumers. We provide assembly services in a wide range of areas, including office and home consumer electronics equipment, telecommunications, and other automotive equipment. We are available for services ranging from printed circuit board assembly to manufacturing of modules and finished goods.Assembly services include:

1.PCB assembly.

2.Surface mount technology (SMT) and Conventional technology (THT).

3.SMD Placement.

4.Assembly concerning environmental regulations (RoHS).

5.Cables harnessing.

6.Integrated solutions for electronic devices.

7.Technical Support Services.

Specialized services cover:

1.Supply of electronic components and printed circuit boards.

2.Technical advice on mass production issues.

3.Coating.

4.Climatic test chamber.

5.Isolation & Continuity test.

6.Functional test Support Services.

What are our advantages?

We have a group of experienced professionals ready to offer you state-of-the-art assembly electronics and manufacturing services. When assembling your electronics, we encompass the latest technology. With us, rest assured of high-quality panels that go into quality control and functional tests before hitting the market.- High-end production assemblies:

- Hard-skilled personnel:

- The most cost-effective:

- Superefficient assembly services:

- Timely quotation and delivery:

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited