What is electronic assembly?

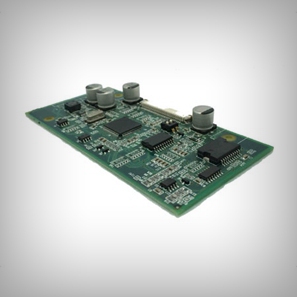

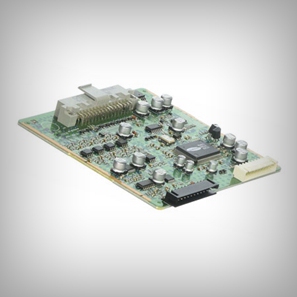

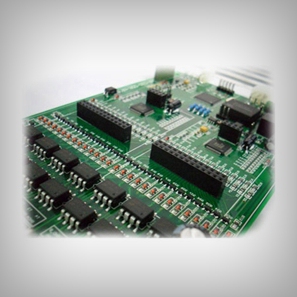

Electronic assembly means a number of electronic components such as circuit elements, discrete components, integrated circuits, or others connected to perform one or more specific functions, replaceable as an entity, and normally capable of being disassembled.Electronic assembly is a general term in electronic product and device manufacturing. An electronic equipment assembler’s responsibilities include working in a factory to assemble various electronic components and computer parts. The business meets diversified production needs by proposing line solutions in pursuit of productivity-focused on SMT (Surface Mounting Technology) equipment for electronic circuit boards production systems or related products such as printing machines and inspection machines.

What is the cost of the electronic assembly?

When it comes to electronic assembly, many factors make much difference to its cost that is comprised of PCB fabrication, electronic component procurement, circuit board assembling, handling fees, and shipping charge, and so on.To sum up, there are several main factors including:

1. PCB technical requirements, such as the number of layers, type of surface, etc.

2. Surface mounted technology or through-hole technology.

3. Single-sided or double-sided SMT assembly.

4. Total number of components.

5. Types and versatility of components.

6. The complexity of printed circuit board assembly.

7. Number of BGA components and parts.

8. The components to be assembled.

9. The number of individual circuit boards.

10. An SMD stencil for paste printing.

11. An additional effort for bonding heavier components to the underside.

12. The component shapes used and the manufacturability of the assembly.

13. The PCB technology deviates from the standard, e.g. Blind buried vias, micro vias, fine conductors, etc.

14. Components that are difficult to obtain or discontinued are used.

In addition, small sizes require more manufacturing technology and high precision in PCB layouts (template data, floor space, etc.). In addition, the time factor also has an impact. If your project is tight, you must specifically adjust your order’s production schedule and complete it quickly.

What services do we offer?

We provide PCB and flex circuit design, fabrication, and assembly for your innovative product ideas. We simplify the complex process of product development by providing printed circuit board design, manufacturing, and electronic assembly services under one roof.Over the years, our electronic assembly services have played a vital role in creating many innovative products ranging from simple gadgets to advanced equipment commonly used by industry and consumers. All aspects of our PCB and flexible circuit operations (including our full set of design services, manufacturing, and electronic assembly) are done in-house.

Also, we have an experienced team, fast turnaround, and unparalleled design, manufacturing, and electronic assembly, which can improve product development efficiency. Our electronic assemblers whose duties include:

Material assembly.

Read and interpret drawings, diagrams, blueprints, specifications, work orders, or reports.

Clean parts thoroughly.

Review work activities under supervises.

Inspect wiring installations, assemblies, and circuits.

Assemble electrical or electronic systems or support structures.

Tag components.

Adjust or repair electrical equipment.

Correct defects.

Test product to ensure conformance to specifications.

Build products such as electric motors, computers, electronic control devices, and sensing equipment.

Perform manual assembly during the small-scale production of electronic devices used in avionic systems, military systems, and medical equipment.

Fabricate or modify parts, using shop equipment.

Verify dimensions and clearances of parts to ensure conformance to blueprint specifications, using instruments, such as micrometers and height gauges.

Populate or modify components on printed circuit board assemblies.

Test functional performance.

What are our advantages?

No matter what challenges you face, we have internal management and production capabilities that can help you throughout the product life cycle while ensuring consistent long-term business growth. We can provide electronic assembly of the following specifications and functions:1. The most cost-effective:

We can reduce your assembly costs through comprehensive solutions specifically tailored to your needs. In addition to saving costs from the assembly process, we can also reduce your costs through our design and pre-engineering services. As an experienced electronic assembler, we provide a large number of electronic assembly services, and a large number of orders every day ensure that we can greatly reduce material expenditure and labor costs, and can provide cost-effective solutions for different needs and ensure the same quality and time.

2. Professional and efficient assembly services:

We can provide a full range of services, from PCB prototyping, circuit board manufacturing, electronic assembly to component procurement services, all of which can guarantee quality and cost-effective prices. Our products are widely used in aerospace, military, automotive, data communications, industrial control, telecommunications, LED lighting, and other fields. Thus, you can get the most intricate designs assembled for testing purposes.

3. Strict quality control system:

From raw material procurement to delivery, we attach great importance to the quality control of each process. We understand the importance of quality to maintaining our customers and don't want to lose any of our old customers because of quality, so we focus on quality. Also, we continuously improve our equipment and develop technologies and management systems adapted to flexible settings without compromising quality.

4. A unique and dedicated team:

All customers know that they are free to consult our assembly and engineering teams at all stages of the project. We enjoy the process of collaboration. All teams are focused on responsiveness, flexible and detail-oriented when changing specifications on any project. Flaws are rooted out early so clients are assured their prototypes are reliable and function according to design.

5. Timely response and personalized service:

As a medium-sized company, we can fully meet the needs of customers and provide timely and personalized services that many large companies cannot provide. Our exemplary customer satisfaction testifies to our ability to impress customers. For old customers with large orders, we have irregular feedback activities, such as free samples and order discounts. We believe that our hard work and loyalty can impress customers.

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited