What is electronic contract manufacturing?

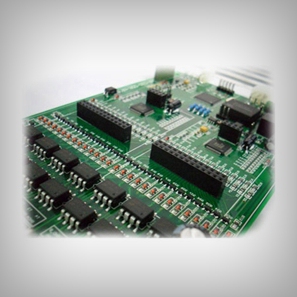

Electronic Contract Manufacturing (ECM) is a service that allows OEMs to offload the manufacturing of electronic devices and assemblies to a third-party producer. It means a variety of services that may include engineering design, subassembly manufacturing, PCB fabrication, turnkey or box builds, functional testing, distribution, and order fulfillment on behalf of OEMs (Original Electronic Manufacturers).Electronic contract manufacturers also provide maintenance and repair services to ensure that the manufactured circuit boards are working as they should. Nowadays most renowned electronic tycoons rely on electronic contract manufacturing.

What are the benefits of electronic contract manufacturing?

There are many advantages to electronic contract manufacturing services for your business. If you are considering seeking a manufacturer to manufacture contract electronic products, you should know that the benefit is not only to find full facilities but also to extend to the entire production process to provide you with the best return on investment. The other benefits of contract electronics manufacturing:1. Better quality:

The world of electronics manufacturing has become extremely specialized in these years. Professional electronics assembly companies are now expected to adhere to multiple international standards such as the ISO series of certifications. However, choosing a company that meets these high standards means better end products for you.

2.Confidence in your engineering:

Engineering raises new questions in the areas of contract electronics manufacturing and sub-PCB assembly. If you choose a contract PCB assembly service with guaranteed supply chain management, then this will no longer be a major issue. If you trust the content in the product, you can trust the content that ends up in the hands of the customer.

3. Get the help you need:

Many outsourced electronics manufacturers also provide design services to top designers, these designers can usually improve your ideas before manufacturing, they also often provide testing and prototyping services, so in every step of the manufacturing process, you can make sure you are making the best product.

What services can electronic contract manufacturing provide?

The most popular of these electronic manufacturing solutions are:1. Surface Mount Assembly;

2. Manual & Automated Thru-Hole Assembly;

3. Surface Mount Assembly (BGA);

4. Cable & Harness Assembly;

5. Electromechanical Assemblies;

6. Conformal Coating;

7. Potting and encapsulation;

8. Contract Electronic Manufacturing Services Quality Systems;

9. Quick turn prototyping;

10. Supply chain management;

11. Circuit board design and engineering services;

12. Printed Circuit Board (PCB) testing;

13. Printed Circuit Board Assembly (PCBA);

14. New product introduction;

How to choose the best electronic contract manufacturing?

Finding an electronics contract manufacturing company perfect for your needs is not a tough task. However, there are 8 factors in choosing an electronic contract manufacturing company:1. Industry and experience:

Hiring an electronic contract manufacturing company with a wealth of industry history and experience is an advantage for your start-up or existing business. Working with a company with a reputation and expertise in the industry, your success can be their success and vice versa. Their reputation is closely related to the performance of your electronic products in the market.

2. Design skills and capabilities:

Electronic contract manufacturing companies should not restrict their services as manufacturers and can conduct further evaluations and corrections to make PCB design as efficient and effective as possible. These opinions and suggestions must have enough knowledge to give ideas and feedback on PCB design, to benefit the final product.

3. Technology advancement:

There is always an opportunity to use technology, tools, software, and other advanced services to take advantage of the electronic products you are manufacturing. Make full use of the latest technology to ensure that your electronic product is developed in the expected top-level way because the high-end technology used to create this electronic product will determine its position in the market.

4. Industry compliance:

You need to constantly update industry standards and ensure that the EMS manufacturing company you work with meets the current standards in the industry. In addition to industry standards, EMS manufacturing companies should also comply with your company’s standards and quality assurance agreements.

5. Product testing:

Product testing is a constant task that is necessary to ensure that all designs pass quality standards and that no one is below quality standards. Product testing will also prove whether the electronics manufacturing company performs poorly and cannot check for defects and problems in product design, which may become problems in future mass production.

6. Production line management:

The electronic contract manufacturing company you work with must be equipped with the correct connections in the industry to ensure that all aspects of production are covered. Electronic contract manufacturing companies must cover all factors such as supply, electrical components, and commodities, and you will only focus on the production and design of electronic equipment.

Why choose us for electronic contract manufacturing?

We offer a variety of electronic contract manufacturing services for the different industries we serve. Here are some of the reasons that confirm why we should be one of your favorite electronic manufacturing companies:·Customer focused teams:

Our customer program launches are supported by offering a dedicated customer focus team methodology, using seasoned EMS professionals together with product experts, to ensure our customers’ success. We provide customer-centric solutions and tailor-made service products to seamlessly integrate with your supply chain requirements.

·Flexibility in service offerings:

From extensive printed circuit board assembly to complex box-build or systems assembly, our facilities are equipped for maximum flexibility and are designed to meet your needs. Additionally, our unique global footprint enables us to provide customers with an adaptable, seamless transition between North America and Asia based on individual program volume needs.

·Better quality and consistency:

Our mission statement is that provide superior quality products and services to fulfill all needs and expectations of our customers on time. We strive to provide the highest level of service in a form that promotes long-term reliability. Also, we have the experience and expertise to produce, test, and improve products for many industries, producing a more consistent product overall.

·Open communication and pricing:

We believe in frequent and open communication and share with all cost drivers and work with customers as a team to achieve maximum value. We provide a great product at a fair price and do so in a transparent manner. Once we understand your specific needs, we will quickly work out a tailored integrated solution to meet your expenses and cost reduction targets.

·Rapid manufacturing process:

We are capable of handling everything in one streamlined process, all services under one roof, so you get the benefit of working with us by one timeline. Our unique prototyping service is due to the fast-tracking of your project during the manufacturing process, so you can get your board back within a few days while still maintaining all certified quality processes.

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited