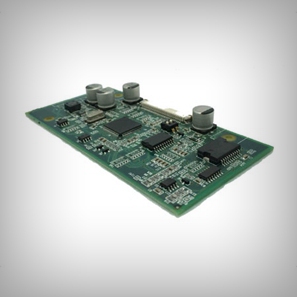

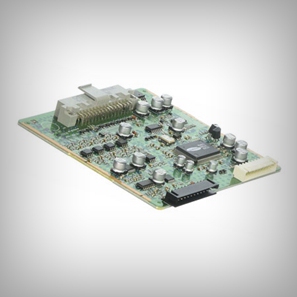

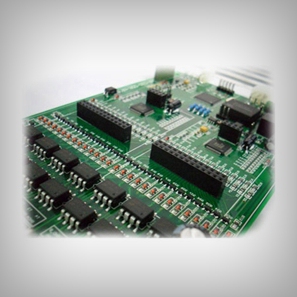

What is printed circuit board assembly?

Printed circuit board assembly (PCBA) is the process of connecting the electronic components with the wirings of printed circuit boards. The traces or conductive pathways engraved in the laminated copper sheets of PCBs are used within a non-conductive substrate to form the assembly.PCB assembly is an important step in the fabrication of the PCB which is an essential component of each and every electronic device and gadget. PCBA means leading technology, state-of-the-art PCB assembly, strict quality testing, and structured manufacturing processes. The assembly process can be completed manually or mechanically, but owing to accuracy and precision, mechanical assembly is the best option for PCB assembly.

What factors affect the assembly cost of printed circuit boards?

Factors affecting the price of printed circuit board assembly are including:·Board type

·Component sourcing

·Number of parts, layers

·Soldering methods

·Inspection approach

·Impedance control

·Solder mask

The cost will vary based on the component type and technology selected by the customer. Furthermore, there are 3 methods of PCB assembly service affecting the cost:

Through-HoleTechnique(THT);

Surface Mount Technique(SMT);

Electro-mechanical assembly.

How to assemble a printed circuit board?

Things needed for PCBA:

1. Printed Circuit Board (PCB)2. Electrical components such as resistors, capacitors, and others.

3. Soldering materials such as wire, preforms, bar, flux, and paste.

4.Soldering equipment such as wave soldering machine, surface mounter, SMT-Stencil, soldering fixture and testing tools, etc.

The various stages in the PCB assembly process including adding solder paste to the board, pick and place of the components, soldering, inspection, and test. All these processes are needed to be monitored to guarantee that product of the highest quality is produced:

Step1: DFM checkDesign for Manufacturing or Design for Manufacturability (DFM) is the optimization of a part, product, or component’s design, to create it cheaper and more easily. This check will find any issues that may severely affect the functionality of the final project.

Step2: Incoming quality control

Before the start of SMT assembly, verify all incoming materials and handle quality issues. If they comply with our strict requirements, our IQC position will check related material issues.

Step 3: Solder paste

The solder paste is a thin and stainless-steel material. Prior to the addition of the components to a board, solder paste needs to be added to those areas of the board where solder is required.

Step 4: Pick-and-Place

The pick and place machine loaded with reels of components picks the components from the reels or other dispensers and places them onto the correct position on the board.

Step 5: Soldering

Once the components have been added to the board, the next stage of the assembly, the production process is to pass it through the soldering machine. Rather than using wave soldering, reflow soldering techniques are used more widely.

Step 6: Inspection

After the boards have been passed through the soldering process they are often inspected. Automatic optical inspection is a far more viable solution. Machines are available that can inspect boards and detect errors, misplaced components, and in some instances the wrong component.

Step 7: Test

After quality checks, it is necessary to test electronic products before they leave the factory. A final inspection will test the PCB for its functionality as it determines the success or failure of the process.

Step 8: Feedback

To ensure that the manufacturing process is running well, it is necessary to monitor the outputs. This is done by investigating any faults detected. The ideal place is at the optical inspection stage as this usually occurs after the soldering phase.

What are the advantages of using printed circuit board assembly services?

In effect, printed circuit board assembly services are extremely accurate and efficient, so they are becoming more and more important in electronics manufacturing. Moreover, only a perfect PCBA service can give the electronic devices which will operate highly precision.·Saving of labor costs and investments

PCB assembly service saves an awful lot of labor costs and investments when you availing service from exterior PCB assembly service providers. Moreover, there are lots of expenses in PCB assemblies, such as setting up operations, managing inventory, hiring labor, upgrading and maintaining all their facilities, and many more.

·Focusing on core powers

With external PCB assembly service providers, your focus will at basic product developments and also on their basic competencies, such as the building of the brand, enhancing sales of your products, and building a better marketing network.

Why should use our printed circuit board assembly services?

Here we are giving you some best reasons that why you partner with us for PCBA service:1. Price per Unit benefits

We are capable of cutting manufacturing costs and eliminate unforeseen expenses. This is because all checks we provided cut down on the number of scrapped boards. Nevertheless, we take into account all the elements and aim to offer competitive prices along with lead-free assembly. We try our utmost to save your money and time.

2. Quality assurance

We are capable of organizing incoming raw materials, process control, refined tests to offer you the best PCB assembly services and we insist on putting quality at the top of every stage of operation including PCB assembly. One of the key reasons why we have become the preferred PCB manufacturer is that we adhere to the industry management system of strict quality standards applicable to our various fields.

3. Extensive experience’s worth

We are a foremost turn-key printed circuit board assembly solutions provider. With years of experience, our experienced personnel and suite of advanced equipment are capable of meeting all of your electronic assembly needs, thus from parts sourcing to PCB assembly, we will provide you with comprehensive professional knowledge and quality assurance.

4. Real-time quotation

You can get a real-time quotation for your PCB assembly inquiry, so you can know how much the order costs immediately. In addition, we set up flexible working hours to cope with the inconvenience caused by international time differences.

5. On-time shipping

These years, we are proud to have been keeping on-time shipping that can only be achieved with the synergy of proper production management, well-trained professionals, and well-designed software, so you can roll out your innovative product faster.

English

English Russia

Russia Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited